Comme des Machines

Future Perfect

The factory of the future is located in Vizcaya. Comme des Machines is revolutionizing the fashion industry by using 3D printing while retaining an artisanal approach. Their machines revive crafts for a digital era that has memory.

Comme des Machines is a nod to the Comme des Garçons, the fashion brand led by Rei Kawakubo. Although the clothes they make in their factory can be seen on the catwalk, their role in the industry transcends design. In 2016, Andrés Iglesias, Jon Michel Azkarate, Suso García León and Aran Azkarate set up in Vizcaya what today is considered to be the factory of the future. With a more efficient, flexible, personalized and sustainable approach, they are revolutionizing the production structure thanks to the use of 3D printing. These 21st-century artisans are one of a kind. At their digital workshop, they conceive pieces for brands such as Burberry, Helena Rohner, Moisés Nieto, Nike, and Palomo Spain. Aran, the company’s CEO, tells us about this model that is transforming fashion.

You refer to yourselves as digital artisans, what does this concept imply?

It explains the philosophy of Comme des Machines. We’ve noticed technology in general, and 3D printing in particular, cause some hostility. But they’re just simple machines that we’re using in a way that is halfway between crafts and industrial production. That’s what sets us apart.

Technological innovations sometimes generate controversy. How would you explain to someone reluctant to this universe the benefits of your production formula?

Machines have to be our allies. They help us get rid of the arduous part of the process and allow us to dedicate ourselves to creating, innovating and investigating. We have to see them as friends. Hence, our mantra is hand and machines, people and machines, working together. The brands that work with us on an ongoing basis have increased their profit margin by up to 30 percent because they use only the resources they need. They’re don’t get overstocked with pieces they won’t sell.

“Machines have to be our allies. They help us get rid of the arduous part of the process and allow us to dedicate ourselves to creating, innovating and investigating”

You are creating fabrics with your 3D printers…

Yes, we’re pioneers in 3D textile creation. Burberry picked us as one of the leading manufacturers of future textiles after we made the best pleated fabric using 3D printing. That was possible thanks to research, and we’re sure the fashion world will want more. More and more countries are now accessing resources that were only available in the first world. By 2030, the population will have increased, and textile demand will be one of the biggest problems facing the industry.

Textile manufacturing is a revolution, what impact will it have on the industry?

Imagine a brand that manufactures garments directly from the pattern. The value chain is shortened, so you can innovate and be creative without taking the risks you usually take using traditional methods.

Brooches printed by Comme des Machines for Dsnú, in collaboration with Angel Schlesser. © Courtesy of Comme des Machines

You have turned machines into artisans. Will crafts survive thanks to 3D printing?

Indeed. These tools will help us extend the life of old crafts. For example, we can create embroidery with them. We invited old embroiderers from Bilbao to our factory and they were very excited about the whole thing. Machines won’t steal anything from us if we don't want them to. But they will engage different generations, types of companies and countries in a dialogue. I think only good things can happen when knowledge is shared.

Besides being sustainable, could we also say that what you do is more democratic?

Indeed! What does a brand that is not Chanel do when it wants to customize products? How does it do it when it only wants to manufacture a few pieces? The big difference with the traditional industry is that we don't use moulds — they are too expensive. We manufacture directly from a computer file. Besides, we don’t demand minimum orders. If a customer needs three pieces, we make them; if they need 40,000, we make them, too. We believe that sustainability goes beyond the manufacturing materials, it involves many other things. You can’t accumulate huge stocks that have to be stored and distributed. We must produce just what we need at any given moment. This is one of our key principles. Nowadays, 3D printing is the only tool that allows us to follow this philosophy.

“We don’t demand minimum orders. If a customer needs three pieces, we make them; if they need 40,000, we make them, too. We believe that sustainability goes beyond the materials”

One must be on the alert to sense all these changes. How did you come to detect it?

The four members of the team have a long history in fashion. We identified a series of deficiencies in the traditional industry that were going to become a problem in the digital era, for example how to manufacture in a sustainable and customizable way. Then, we launched a research project that is still running today to develop healthier and fairer factories using digital technologies. We realized that 3D printing allowed us to do all this. At first, everyone criticized us, but over time they’ve proved us right.

Collaboration of Comme des Machines with Sur / Sac. © Courtesy of Comme des Machines

Going back to sustainability, what are the sustainable materials you work with?

We use PLA, a biopolymer made with natural ingredients such as sugarcane, coffee and potatoes, among others. It’s biodegradable and compostable. We also print cement, wood, and mud made from waste.

Hearing you speak, I perceive the passion you feel for your work. What motivates you the most?

The fact that big and small brands, like us, work together to build a more creative, sustainable and healthy future. In the twenty years that I’ve been dedicated to fashion, I never thought I would see something like this. I think there’re many reasons to be optimistic. You also see that on the street, because the customer loves to see that the product has been created fairly, following sustainable standards and using high quality biomaterials. I was ardently waiting for this to come.

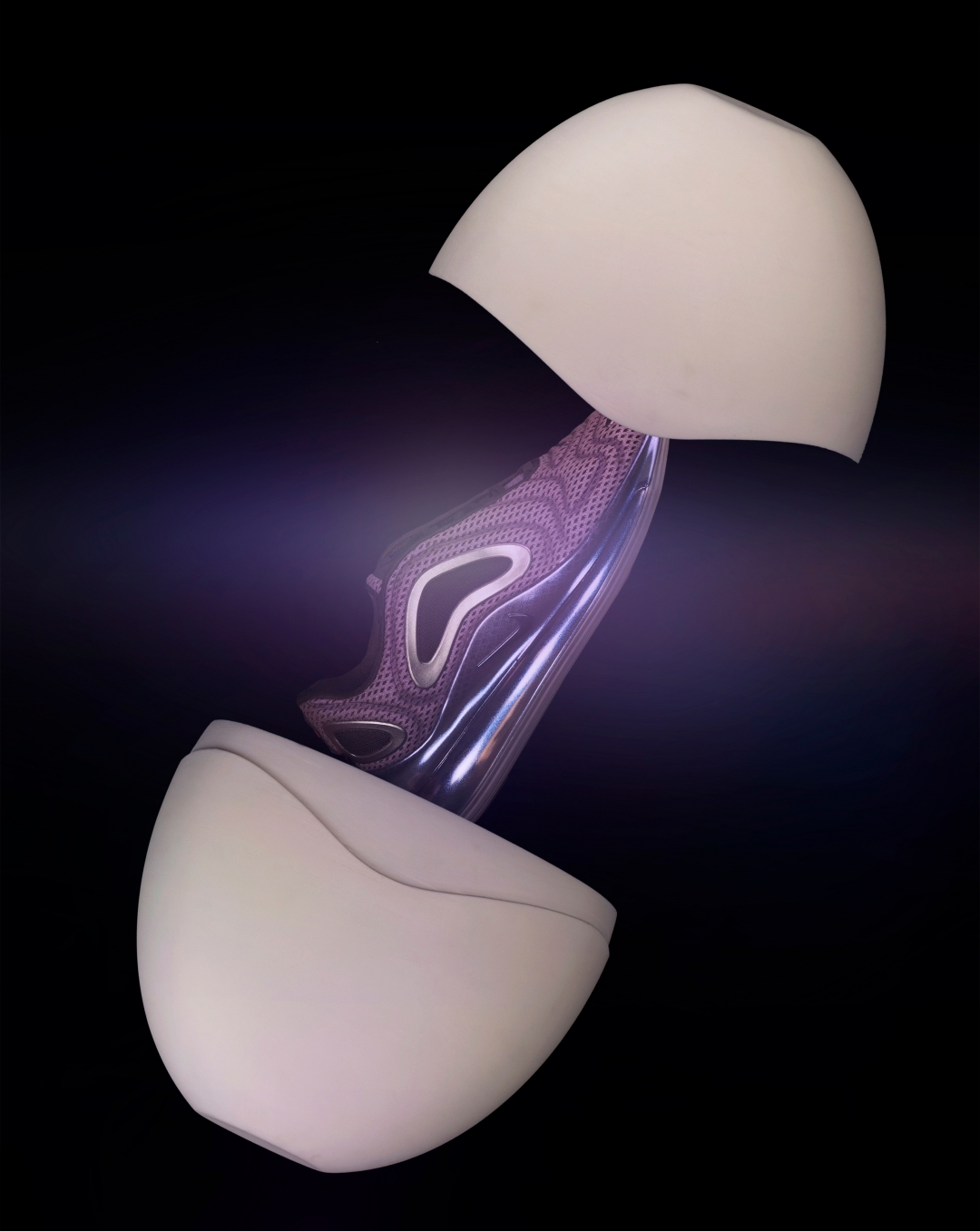

Collaboration of Comme des Machines with Nike. © Courtesy of Comme des Machines

What, from among all your projects, would you keep?

In February we’re launching an absolutely revolutionary collaboration with a Spanish mass market brand aimed for all audiences. It will be the first collection of this kind developed with 3D printing. It has been one of the most interesting projects I’ve ever worked on because it required building a new methodology. We had to conceive the piece but also an entire structure to supply a company of that size. In my opinion, this symbolically embodies the new century.

How has 3D printing changed since you started in 2016?

When I started off, there were only yellow, blue, red and green available, and doing something interesting with those colours was a real challenge. Now we can choose, for example, from among many different types of woods with beautiful, subtle hues. We can even mix them, which wasn’t possible before. Eventually, everything from electronic devices to stem cells, will be printed. The future will be entirely 3D printed.

3D-printed fabric belonging to the ongoing research and innovation project NORA, by Comme des Machines. © Courtesy of Comme des Machines